Walnut processing

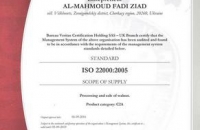

supercash com ua At our company, walnut processing is performed in accordance with the requirements of the sanitary epidemiological service, fire inspection, labor protection service, environmental service, as well as all other accompanying inspections and control bodies, which is confirmed by the ISO 22000 certificate, which is the generally accepted standard in the world Food safety.

But the availability of certificates and other documents is not the main thing, as in any other business, and most importantly with what love the team of the enterprise refers to the work, what results they wish to achieve and whether they work synchronously in one direction. We have been exporting walnut since 2004, we started as a majority without high-tech equipment, but had a great desire to develop and process walnuts in Ukraine according to European standards. Understood that to enter the world market we need the ideal quality of the walnut kernel, a very flexible price policy and well-established logistics.Years passed, we bought the newest line for processing walnuts, built our own laboratory and assembled a team of like-minded people, the foundation of our enterprise is not equipment for processing walnut, but people are our team. After all, business will be successful at 90% if its employees are related to working with love and do all the work perfectly, both for themselves.

For the processing of walnuts by European standards we have:

– Established partnerships with proven farms, from which we purchase walnuts, which allows us to forecast the yield of walnut this year, as a consequence of its price;

– Our own laboratory, which strictly controls all stages of processing walnuts, from purchased raw materials to packing the sorted walnut kernel. It prevents from getting into the finished product: wet, not sufficiently formed (shriveled), with mold, foreign taste or smell, damaged by insects of the kernel, as well as the possible ingress of shell or other foreign objects;

– A new line for processing walnut, produces about 220 kg / hour, while the possibility of adjusting the value of compression of the stitch plates, there is an optimal split of the nut, and this is the maximum yield of halves. Sorting by color is done only manually, on special lines, then in the drying chambers we bring the core of the walnut to the optimum humidity – no more than 5%;

– Territory and warehouses for proper storage of walnut, they are best kept in the shell and processed immediately before shipping to the customer. And if the finished core also has to be stored, then not for long, in a dark and cold room reserved only for storing the nut, without foreign smells, which can be absorbed by the core, without shell fragments and with established climate control;

– And most importantly – it is a meticulous approach of the whole team when processing walnuts and storing it;

The processing of walnuts consists of the following stages:

- Calibration of the nucleus. At this stage, the walnut kernels are sorted into halves (1/2), quarters (1/4) and eight o’clock (1/8), while the walnut is cleaned from the shell and the membranes;

- Sort by color. On special lines, manual sorting is performed, in which the nut is sorted by color (extra, light, light amber and amber);

- Drying. The peeled nut is dried in special drying chambers.

- Packing of products. Purified walnuts are packed in cardboard boxes of 10 kg or in vacuum bags of 2 * 5 kg.